mpn:

brand:

manufacturer:

MPN:

Description:

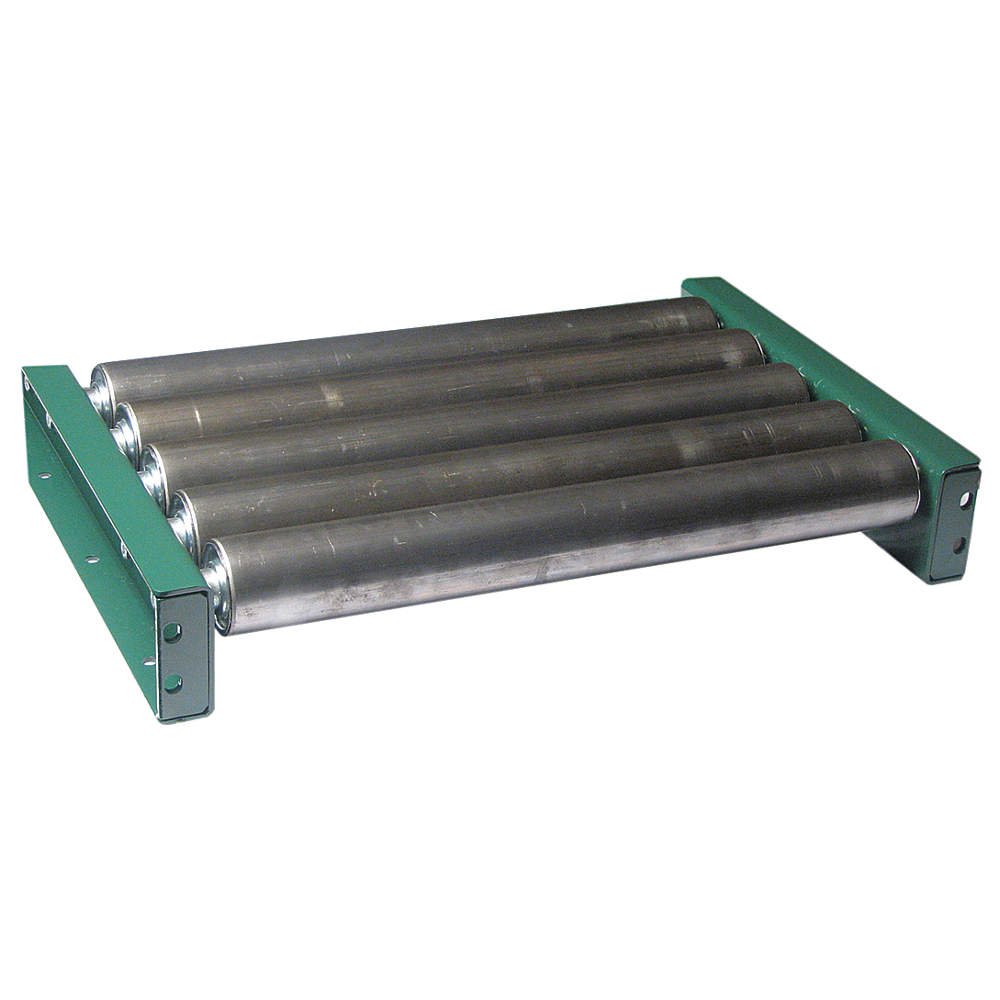

Extra-heavy-duty roller conveyors with steel frames are more resistant to impact and shock and have a higher weight capacity than light-duty, medium-duty, and heavy-duty roller conveyors. They are ideal for conveying very heavy items such as large pallets, castings, sheet metal, and metal bins. Also called conveyor sticks, rigid-frame conveyor sections consist of rollers that are mounted on a series of axles attached to rigid frames. The sections may be straight or curved and can be connected to create a conveyor that allows items to roll along a path from one place to another, reducing the physical effort it takes to move the loads. Butt plates on the ends of the conveyor sections can be bolted together to join multiple sections. Each section must be supported by compatible conveyor stands. The number and spacing of the stands used to support the conveyor section will affect its capacity. Roller conveyors consist of rollers that are mounted on a series of axles attached to rigid or telescoping frames. These unpowered (gravity-flow) conveyors use a downward slope or a manual push to move loads down the line. The rollers provide a stable surface for moving loads with rimmed or uneven bottoms, such as drums, pails, pallets, skids, and bags. They allow the loads to roll along a path from one place to another, reducing the effort it takes to move the loads in package handling, warehousing, dock, assembly, or inspection tasks. Loads roll forward and back along the conveyors and can be pushed from side to side across the full width of the conveyors. Roller conveyors typically offer more weight capacity than skate wheel conveyors. The conveyor's roller spacing density affects the size of the items that can be conveyed on it. The smallest item on the conveyor should be supported by at least three rollers at all times. This listing is for each. Item : Roller Conveyor Conveyor Frame Type : Rigid Bed Material : Structural Steel Frame Finish : Powder Coated Bearings : Ball